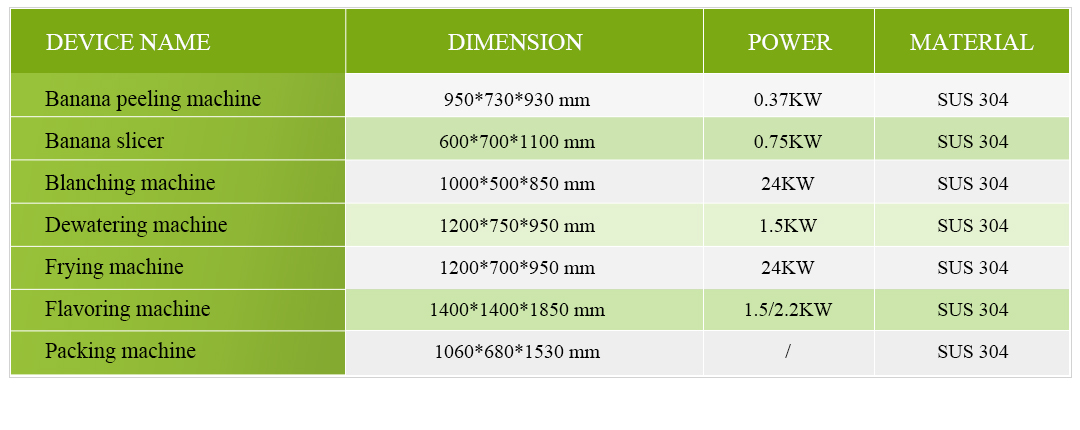

This fried banana chips production line mainly consists of banana peeling machine — banana slicer — blanching machine — dewatering machine — frying machine – deoiling machine –star anise seasoning machine –420 Typ automatische Verpackungsmaschine — air pressure Mechanism nitrogen machine – metal detector – sealing machine.

Arbeitsprozess

1.Banana Peeling: The process begins with the peeling of the banana. With the help of banana peeling machine, the peels can be effectively removed without damaging the banana flesh.

2.Banana Slicing: The peeled bananas are sliced into thin, uniform slices by the slicing machine. Our slicer has the features of smooth surface, fast cutting, easy cleaning and simple operation, which can save manpower and cost.

3.Blanchieren: Blanchieren ist ein notwendiges Verfahren. Put the banana slices into the blanching machine with a water temperature of about 65-90℃, die die Enzymaktivität zerstören können, Verbesserung und Erweichung der Gewebestruktur, make it easy to dry, and also prevent frying and foaming.

4.Dewatering: Processed banana slices need to be drained, using a dehydrator to remove excess moisture and make them easier to fry.

5.Braten: Die Frittierzeit beträgt 2-3 Minuten und die Frittiertemperatur beträgt 170-180°C. The dried banana slices are deep-fried in oil at controlled temperatures until they become crispy and golden brown.

6.Seasoning: Nach dem Braten, the chips can be seasoned with various flavors such as salt, spices, or other flavorings. This can be achieved through a star anise seasoning machine.

7.Verpackung: The final step is to package the banana chips into bags, Beutel, oder Behälter. 420 Automatische Verpackungsmaschinen sorgen für eine ordnungsgemäße Versiegelung und einen Schutz des Produkts, um die Frische zu erhalten und die Haltbarkeit zu verlängern.

Lieferant von Lösungen für die Lebensmittelverarbeitung

Lieferant von Lösungen für die Lebensmittelverarbeitung

WeChat

Scannen Sie den QR-Code mit wechat