This set of French fries production line is designed to handle various stages of the manufacturing process, from raw potatoes to the final packaged French fries ready for distribution and consumption. The whole line is mainly composed of lifting feeder, máquina de eliminación de piedras de limpieza de rodillos, máquina peladora de cepillos, cutting machine, máquina de limpieza de burbujas de aire, freidora continua de tipo rotativo, drum seasoning machine and 420 Tipo máquina de envasado automática.

Equipment of The Production Line

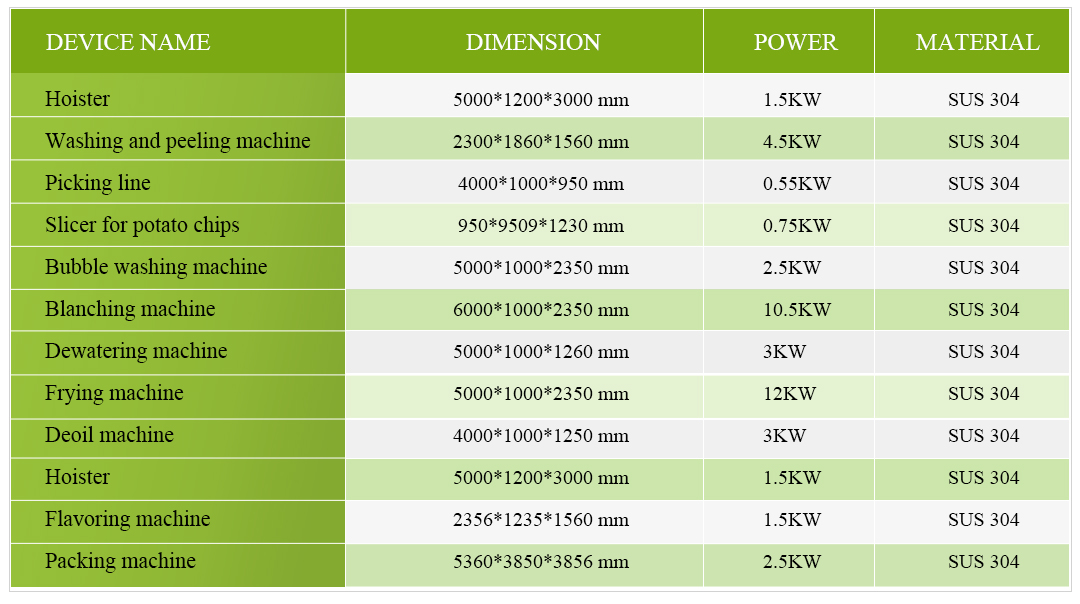

1. Ascensor: It is used for material lifting and conveying. The potatoes can be easily poured into the hopper manually, and the material can be continuously and evenly lifted to the next process through the conveyor belt, which saves a lot of labor and is convenient and practical.

2. Cleaning and peeling machine: The potatoes that come in can be cleaned and peeled, and the materials are fed and discharged at the same time, which can work continuously.

3. Picking belt: To pick and repair the cleaned and peeled potatoes. If there are any bad ones, they need to be picked out.

4. Potato cutter machine: Put the peeled and clean potatoes into the feeding port continuously, and the French fries will be automatically cut out.

5. Rinsing machine: Wash the starch of French fries.

6. Blanching machine: Blanch and fix the color of French fries, and add food additives.

7. Cooling machine: Cool the blanched French fries to prevent sticking.

8. Air-cooled dehydrator: Dry the moisture on the surface of the blanched French fries for frying.

9. Frying machine: Fry French fries. The temperature can be automatically controlled and it can work continuously.

10. Deoiling machine: Take off the oil on the surface of fried French fries.

11. Picking belt: Blow the French fries to cool for packaging, and pick unqualified fries.

12. Seasoning machine: Season the selected French fries.

13. Packing machine: Pack French fries.

Proveedor de soluciones de procesamiento de alimentos

Proveedor de soluciones de procesamiento de alimentos

I wpuld tô leve tô know more about , literalmente proces and delivery , i am living in saindo but want tô back tô Brasil my contra tô start a bussines there.

dear sir/madam

i am malik from Bangladesh .

i want to some vegetable chips machine which i make many kinds of chips

and French fry making machine. so need your help with your machine details and

how will set up production line diagram . so please give me details your machine at my

mail address: rafathmalik@gmail.com and whats app +88 01863626027. waiting for your further reply.

Best Regards

Malik

Hola

Hi please I want to find out about the cost for this French fries cutter machine , I am in Ghana and I would like to hear from you.