Le surgélateur de type tunnel est un appareil conçu pour la congélation rapide de divers produits alimentaires, y compris les légumes, fruits, fruits de mer, Viandes, Produits laitiers et plus encore. Il se compose d’une série de convoyeurs à bande de refroidissement et de maille. La nourriture voyage sur ces ceintures, exposés simultanément à l’air glacial qui les entoure. La courte durée de mouvement des aliments sur ces bandes permet une congélation rapide des produits, atteindre rapidement des températures sûres et minimiser les possibilités de croissance bactérienne.

Cette machine de congélation adopte un système de convoyage tridimensionnel avec une structure compacte et un faible encombrement, Garantir des performances stables et fiables. Il s’agit d’un nouveau produit efficace et économe en énergie, Consommer 30-40% moins d’électricité par rapport à des produits similaires. La structure compacte et la conception optimisée des conduits d’air contribuent à d’excellents résultats de congélation. La combinaison d’un contrôle API et d’une interface conviviale permet un contrôle flexible et une utilisation facile.

Après congélation, Les aliments conservent au maximum leur texture et peuvent être conservés pendant une période prolongée, ce qui le rend adapté au transport longue distance tout en préservant le goût et la qualité des aliments. La machine fonctionne de manière entièrement automatique, Économie de temps et d’efforts, ce qui est largement apprécié par les usines alimentaires.

- Détails du produit

- Fonctionnalités

- Application

- Enquête

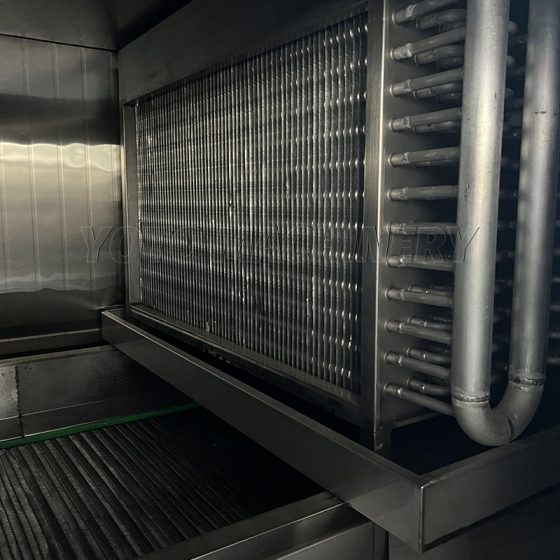

1.Le système de réfrigération du compresseur est respectueux de l’environnement, élimine efficacement les odeurs et les bactéries, économise de l’énergie, et a de faibles coûts d’exploitation. Le dispositif unique de guidage de l’air assure une distribution rationnelle de l’air, permettant un flux d’air uniforme et une efficacité de congélation élevée en exposant entièrement les matériaux à un fort air froid.

2.La bande transporteuse d’aliments à vitesse réglable convient au traitement flexible de divers produits surgelés. Équipé d’un dispositif de réglage de la tension pour la bande transporteuse, Il assure un fonctionnement fluide et durable.

3.Le système de contrôle dispose de deux modes: Réfrigération automatique et manuelle, offrant aux utilisateurs la possibilité de choisir en fonction des différents besoins de production. Le congélateur de type tunnel à compresseur est stable, durable, Facile à utiliser, et a une longue durée de vie. L’équipement peut être personnalisé en fonction des besoins personnalisés des utilisateurs.

Convient pour le traitement de grands volumes, les équipements de congélation rapide dans les lignes de production d’usine, Peut être personnalisé

Produits à base de viande: Brochettes de viande, Cuisses de poulet, ailes de poulet, Cubes de viande, boeuf en dés, pattes de poulet, Pieds de cochon, etc.

Produits aquatiques: crevette, filets de poisson, calmar, Pétoncles, chair de palourdes, morceaux de pieuvre, mulet, etc.

Produits à base de pâtes: Boulettes, Wontons, boulettes de riz gluant, Petits pains cuits à la vapeur, Petits pains cuits à la vapeur, Rouleaux de fleurs, rouleaux de printemps, etc.

Produits à base de fruits: Fraises, Pommes, bleuets et autres fruits.

Produits végétaux: traitement surgelé de divers aliments surgelés tels que le gombo, chou-fleur, radis, etc.

Fournisseur de solutions de transformation des aliments

Fournisseur de solutions de transformation des aliments

Salut,

C’est Bilal d’Alshaheer Foods, Karachi, Pakistan. Nous recherchons un tunnel de congélation/congélateur cryogénique pour notre usine de transformation de la viande. Ci-dessous, veuillez vérifier nos exigences:

Spécifications du congélateur cryogénique

1. Capacité: 400-1000kg/heure

2. Méthode de congélation: Cryogénique (Utilisation d’azote liquide ou de dioxyde de carbone liquide)

3. Plage de température: -70°C à -196°C

4. Temps de congélation: Congélation rapide en 3 minutes pour assurer la qualité et la conservation de la texture

5. Matériel: Construction en acier inoxydable pour l’hygiène et la durabilité

6. Vitesse de la courroie: Vitesse de la bande transporteuse réglable pour contrôler le processus de congélation

7. Isolation: Isolation de haute qualité pour minimiser les pertes d’énergie

8. Caractéristiques de sécurité: Capteurs d’oxygène, arrêt d’urgence, et systèmes d’alarme

9. Automatisation: Systèmes de contrôle programmables pour une facilité d’utilisation

10. Nettoyage: Conception facile à nettoyer avec accès pour l’assainissement et l’entretien

11. Conformité: Doit répondre aux normes de sécurité alimentaire et de qualité (Par ex., HACCP, ISO)

Salut

C’est Alana, Votre produit nous intéresse, Partagez votre catalogue de produits

à notre email ci-dessous

Courriel de contact: Alanahaigharmy@hotmail.com

Cordialement

Alana

I like your machine