This fully automatic vertical packing machine for sauces and liquids is an automated packaging device specifically designed for packaging liquid and sauce products in a vertical orientation. This machine is designed to accurately fill liquid or sauce products into pre-made packaging bags, bottles, or other containers. It’s suitable for the packaging of sauce and liquid materials in various industries, including food, pharmaceuticals, chemicals, personal care, condiments, etc., such as shampoo, shower gel, jam, seasoning packets, sauce packets, etc.

- Product Details

- Features

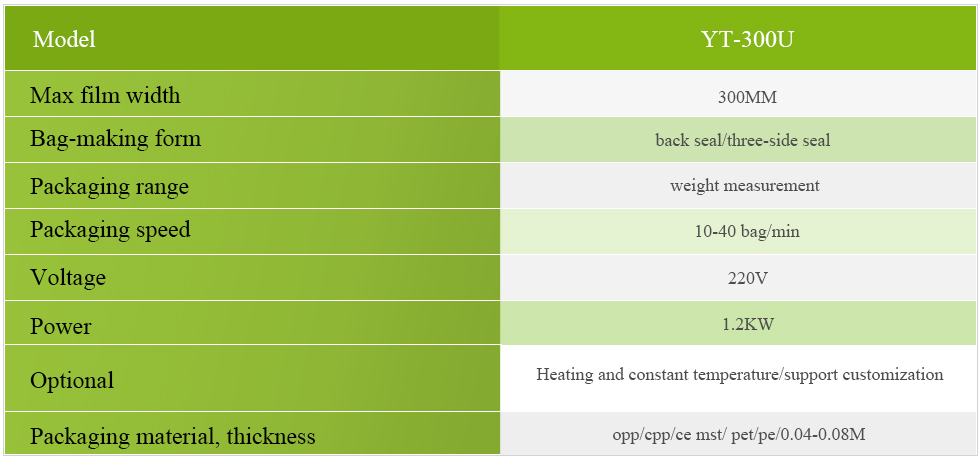

- Parameters

- Inquiry

1. Back sealing or three sides sealing. Pretty package form and count accurately.

2. Use multi path temperature controlling and heat sealing organ, controlling temperature accurately, good heat balance and high quality of sealing. Suitable for packing multi materials;

3. Granule packing machine use shaking container to adjust the device adjusting the package capacities at random in the process to improve the working efficiency. Packing materials are like desiccant, tea and medicine and so on.

4. Powder packing machine use the latest hopper feeder which can be changed its height freely in order to avoid the readjustment after cleanout and improve the working efficiency. Packing materials are like albumen powder, coffee and flour.

5. Liquid and catsup packing machine makes use of stainless steel. Due to applying domestic advanced suction technology, there is no material pressed and leaked. Package capacity can be adjusted infinitely in stated range. Be suitable for packing honey, pesticide and cosmetic and so on.Especially that semi-fluid model has back siphonage function that can avoid clamping and leakage.

food processing solutions supplier

food processing solutions supplier

WeChat

Scan the QR Code with wechat